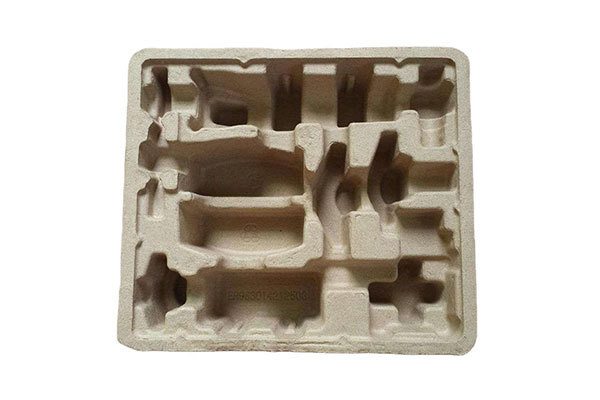

Industrial Packaging Tray Making Machine 4 Molds Apple Tray Machine

Payment Terms:

LC

TT

Keywords:

Industrial Packaging Tray Making Machine 4 Molds Apple Tray Machi

- Product Details

- Parameters

-

Pulping System

1. Put the raw material and water into the hydraulic pulper, you will get the paper pulp after mixed 10-20 minutes.

2. Pulp pump will transfer the finished paper pulp into the slurry pool.

3. The pulp pond beater will mix the pulp concentration.

4. The pulp pump will transfer the pulp into forming machine.Molding System

1. The molding machine is to absorb the pulp to the molding mold, absorb the pulp to the molding mold through the suction of the vacuum system to absorb the excess water into the gas-water separation tank, and then pump the water to the tank for storage.

2. The molding mold adsorbs the pulp and then forms it. and then the transfer mold takes out the finished product and sends it to the they drying tray.Drying System

1.Heat source: natural gas, diesel, liquefied petroleum gas and other combustion liquids and gases. The transmission mode adopts industrial transmission chain to drive the net plate transmission, which runs in the drying line.

Egg tray making machine

Egg tray making machine refers to the machine that can be used to make paper egg trays. Paper egg trays, as a kind of protective shell to hold eggs, are becoming the mainstream packaging product on the market. Jinan Wanyou Packing Machinery Factory egg tray machine enables customers to make egg trays with higher quality and higher bearing capacity. Due to low cost and high return, more and more people are willing to invest in the machine. Especially for chicken farmers, they can sell the eggs packaged by egg trays at a higher price. If you are interested in the profitable business, contact us now!

FAQ

Our production line has Fully Automatic and Semi Automatic two types , both have computer control system .

1. What is Semi Automatic type ?

If only order The 1st and 2nd compulsory parts , that's Semi Automatic because you'll have to do the work of drying up egg tray manually;2. What is Fully Automat type ?

Meaning: the production line includes the Drying system and the whole procedure can be done Automatically .

Of course, the price and the required work space would have big difference from the semi-automatic type.3. Quality

-- Our machines use UK Technical and part of the components are Germany-made (ex: Ball valve) .

-- Our machine is made by Tooling NOT by Welding , insuring a minimum of 10 years’ lifespan .

-- The Egg tray moulds material is Aluminium which can keep the fixed shape much better than that made of rubber material.

-- 99.9% of Success rate: Even if there is a failed egg tray , just throw it back to Pulping area and it can be re-used avoiding waste ;

-- Our machine has been sold to worldwide for over 10 years with continued re-order by some customers with their business grow .4 .What capacity per hour do you offer ?

Our machines’ capacity is from 350pcs/hr to 6000pcs/hr.5.Do your products come with a warranty ?

Yes , we have 2 years warranty according the international practice.6.Can I customize this kind of machine from your factory?

Yes ,we offer custom-made service to our customers, you need to provide us some samples,such as photos,dimensions etc. -

Main parts

Pulping system

Including :

water pump-2sets

pulp pump -2sets

1M³pulping machine –1setsForming system

Including

4 moulds forming machine -1set

Vacuum pump-1set

Compressor -2sets

Washer –1set

Vacuum tank-1pcs

Air tank—1pcsDrying system

Including

Drying oven –1set

(L 15M*W2M*H2.2M)

Chain and trays –1sets

Hot air pipe –1sets

Chain wheel with shaft—1sets

Delivery belt –1set

Drive motor –1setBoiler

Including

Boiler –1set

Natural gas burner-1set

Fan with motor -1set

Electric control -1setEgg Tray Mold Quantity

4pcs

Raw material

Waste paper

Egg tray Capacity

1300-1500pcs/hour

Net weight per piece (gram)

70g-75g

Waste paper consumption

97.5kg / hour

Water Consumption

0.2ton / hour

Natural Gas Consumption of Dryer

50cbm/h

Worker requirement

4-6workers

Machine Length

8m-28m

Machine weight

8-30tons

Power Requirement

Without dryer

45KW

With dryer

65KW

Area of workshop

Without dryer

More than 150 M²

With dryer, dryer-18m

More than320M²

Container Requirement

Without dryer

40ft*1

With dryer

40ft*3+20*1

Remarks:

1. The egg tray Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g).

2. Workshop size is for reference only and could be adjusted according to actual size of client’s plant.

Previous Article

Previous Article

Get a Free Quote

INSTALLATION AND DEBUGGING

- About 5-30 days installation and debugging;

- Technical consultation;

- Detailed design of customer workshop;

- Installing and testing the whole production line before shipment

TRAINING

-

Training engineers and workers;

-

About 2-5 days Training;

-

The engineer takes photos and videos in each step.

-

Take notes and ask the customer to signature for each step completion.

MAINTAINING

-

Remote after service. When there’s something wrong with the electric appliance software of the forming machine in customer’s factory, Jinan Wanyou company will remote check by network.

-

Reply within 12 hours.

-

Solutions are given within 24 hours.

-

Ensure timely, efficient and low cost of solving problem.

AFTER SALES SERVICES

-

We present Spare parts(1 year for free usage)

Suggest customer to buy necessary Spare Parts and Quick-Wear part for 2 years. -

Whole machine main part guaranteed for 2 years.

-

10 years for the forming machine lifetime.

-

20 years industry experience in the paper egg tray machine.

Questions & Answers

Q

Can we visit the factory?

A

Welcome at any time, and provide pick-up service.

Q

What are the ways of equipment installation and maintenance?

A

The equipment is easy to install and maintain. We randomly match the manual and spare parts of wearing parts, and can provide offline on-site support during the warranty period. Lifetime free online service.

Q

Where is the transportation port?

A

Usually Qingdao port, or customer-specified port.

Q

How long does it take for delivery?

A

The delivery time is different for different models, usually 2 to 3 months.

Q

What payment methods do we support?

A

TT, LC mainly.

Series of Products