Rotary 5+8 Molds Paper Egg Tray Production Line

Payment Terms:

LC

TT

Keywords:

Rotary 5+8 Molds Paper Egg Tray Production Line

- Product Details

- Parameters

-

Product Description

Egg tray machine is used to make paper egg trays. The egg tray forming machine can be divided into manual egg tray machine(350-1500pcs), semi automatic machine(2000-4000pcs) and automatic machine(4000-6000pcs). Ask the egg tray machinery price now!

The automatic egg tray machine production line is equipped with one drying system, after mixing pulp process and forming process, the wet egg trays will be transferred to the drying oven automatically by chains, and then product can be dried in the oven with hot air supplied by the boiler. The automatic egg tray machine is suitable for clients who wants big capacity of paper egg tray/egg carton/shoe tray/ bottle tray demand.

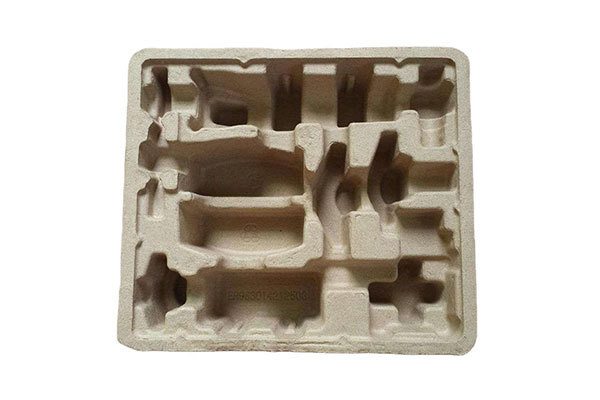

End Products of Paper Egg Tray Machine

Paper egg trays are the end products of egg tray plant. Egg trays are good protection shell for eggs during transporting and storage. Usually, the egg trays has 30 holes. What’s more, if you change the mould, the machine can be used to make apple trays, egg cartons and so on.

Raw materials to make egg trays: original wood pulp, craft paper, A4 paper, paper box, old newspaper, old books and other kinds of recycled papers.Why Choose Wanyou Paper Egg Tray Machine

Rich export experience: egg tray making machine of Wanyou has been exported to Algeria, Egypt, India, Botswana, Columbia, Nigeria, Bolivia, Indonesia, Ghana, Sudan, Hungary, Dominica, Zambia, Tanzania, Cote d’Ivoire, Sri Lanka, Jamaica, the Philippines, Russia, Ukraine, Uganda, Australia, Argentina, Brazil, Saudi Arabia, Libya, Syria, Mozambique, United Arab Emirates, Kyrgyzstan, Romania, Berlin, Pakistan, and so on.

Professional manufacturer: Wanyou Machinery, with 10+ years’ manufacturing experience, supplies higher-quality egg tray machine for customers from all over the world. Through years of innovation and upgrading, it fully satisfies most customers’ demands and takes the leading position in the global paper packaging machinery industry. Wanyou aims at providing superior and high-tech paper egg tray machines for customers around the world in the near future.

Customized service: commonly, there are 30 holes egg tray, 6 egg box, 12 egg box, 18 egg carton, apple trays, seedling trays, industrial packaging trays, etc. Meanwhile, egg carton mould, apple tray mould, coffee cup tray mould, shoe supporting tray, bottle tray mould, industry packaging tray mould are available for you. Certainly, you can send us the paper tray pictures that are sold well on your market. If you need, we can customize it for you.

Short delivery time: 10-20 work days

Note: the actual delivery time depends on the paper egg tray machine model and egg tray drying line that you choose.

Our Services

(1)Technical consultation ;

(2)Detailed design of customer workshop ;

(3)Installing and testing the whole production line before shipment;

(4)Training engineers and workers;

(5)Supplying spare part for long time;

(6) Online services within 12 hours. -

Egg Tray Mold Quantity

40 (5pcs*8)

Raw material

Waste paper

Egg tray Capacity(pcs/hour)

5000

Net weight per piece (gram)

70-75

Waste paper consumption

375kg/h

Water Consumption

1.1t/h

Natural Gas Consumption of Dryer

150cbm/h

Boiler model (natural gas fuel Kcal)

1800*103

Worker requirement

10-12

Power Requirement

Without dryer

Not suggested

With dryer

180kw

Area of workshop

With dryer

600m²

Dryer 36mContainer Requirement

Without dryer

Not suggested

With dryer

40hq*4

Remarks:

1. The egg tray Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g).

2. Workshop size is for reference only and could be adjusted according to actual size of client’s plant.Model

Capacity

Forming machine

Drying system

Workshop space

Rated power

WY-1500S

1500-2000pcs/hr

3molds *4faces

Single-Layer Metal

55m*10m*6m

130KW

Rotary type

WY-1500M

1500-2000pcs/hr

3molds *4faces

4 Layers

35m*10m*6m

120KW

Rotary type

Metal

WY-2000S

2500-3000pcs/hr

4molds *4faces

Single-Layer Metal

60m*10m*6m

165KW

Rotary type

WY-2000M

2500-3000pcs/hr

4molds *4faces

4 Layers

40m*10m*6m

145KW

Rotary type

Metal

WY-4000S

4000pcs/hr

4molds *8faces

Single-Layer Metal

75m*15m*6m

239KW

Rotary type

WY-4000M

4000pcs/hr

4molds *8faces

4 Layers

50m*15m*6m

223KW

Rotary type

Metal

WY-5000S

5000pcs/hr

5molds *8faces

Single-Layer Metal

70m*15m*6m

298KW

Rotary type

WY-5000M

5000pcs/hr

5molds *8faces

4 Layers

55m*15m*6m

273KW

Rotary type

Metal

WY-6000S

6000pcs/hr

6molds *8faces

Single-Layer Metal

80m*15m*6m

365KW

Rotary type

WY-6000M

6000pcs/hr

6molds *8faces

4 Layers

55m*15m*6m

326KW

Rotary type

Metal

Previous Article

Next Article

Previous Article

Next Article

Get a Free Quote

INSTALLATION AND DEBUGGING

- About 5-30 days installation and debugging;

- Technical consultation;

- Detailed design of customer workshop;

- Installing and testing the whole production line before shipment

TRAINING

-

Training engineers and workers;

-

About 2-5 days Training;

-

The engineer takes photos and videos in each step.

-

Take notes and ask the customer to signature for each step completion.

MAINTAINING

-

Remote after service. When there’s something wrong with the electric appliance software of the forming machine in customer’s factory, Jinan Wanyou company will remote check by network.

-

Reply within 12 hours.

-

Solutions are given within 24 hours.

-

Ensure timely, efficient and low cost of solving problem.

AFTER SALES SERVICES

-

We present Spare parts(1 year for free usage)

Suggest customer to buy necessary Spare Parts and Quick-Wear part for 2 years. -

Whole machine main part guaranteed for 2 years.

-

10 years for the forming machine lifetime.

-

20 years industry experience in the paper egg tray machine.

Questions & Answers

Q

Can we visit the factory?

A

Welcome at any time, and provide pick-up service.

Q

What are the ways of equipment installation and maintenance?

A

The equipment is easy to install and maintain. We randomly match the manual and spare parts of wearing parts, and can provide offline on-site support during the warranty period. Lifetime free online service.

Q

Where is the transportation port?

A

Usually Qingdao port, or customer-specified port.

Q

How long does it take for delivery?

A

The delivery time is different for different models, usually 2 to 3 months.

Q

What payment methods do we support?

A

TT, LC mainly.

Series of Products