Rotary Forming Type 3+4 Molds Egg Tray Making Machine

Payment Terms:

LC

TT

Keywords:

Rotary Forming Type 3+4 Molds Egg Tray Making Machine

- Product Details

- Parameters

-

Paper Egg Tray Machine Working Process

Pulping System

1. Put the raw material and water into the hydraulic pulper, you will get the paper pulp after mixed 10-20 minutes.

2. Pulp pump will transfer the finished paper pulp into the slurry pool.

3. The pulp pond beater will mix the pulp concentration.

4. The pulp pump will transfer the pulp into forming machine.Molding System

1. The molding machine is to absorb the pulp to the molding mold, absorb the pulp to the molding mold through the suction of the vacuum system to absorb the excess water into the gas-water separation tank, and then pump the water to the tank for storage.

2. The molding mold adsorbs the pulp and then forms it. and then the transfer mold takes out the finished product and sends it to the they drying tray.Drying System

1.Heat source: natural gas, diesel, liquefied petroleum gas and other combustion liquids and gases.The transmission mode adopts industrial transmission chain to drive the net plate transmission, which runs in the drying line.Advantages of our egg tray machine

easy operation

high quality spare parts

long service life of the machine

simple installation

beneficial to the environment

waste paper recycled

water recycled

no pollution to the environment

No waste is generated.

Suitable for small businesses.FAQ

(1). What kind of material we can use as the raw material?

Any kind of waste paper like old newspaper,magazines,books,A4 paper etc, and easy to get(2). What kind of Fuel can be used for the whole production line?

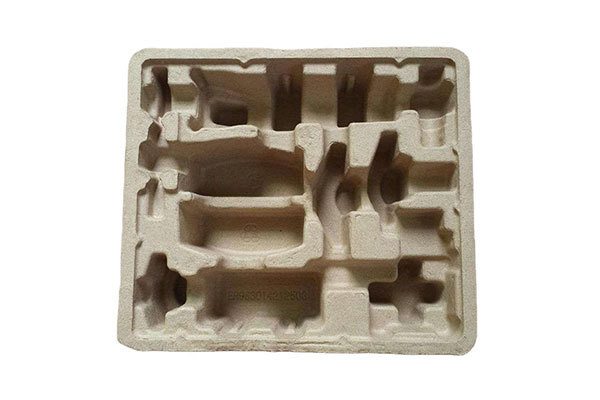

Coal, natural gas, and diesel oil.(3). What kind of products can be made by this machine?

All paper package such as paper egg tray, egg carton,egg box, fruit tray, bottle tray, cup tray, consumer product package, medical disposable container etc.(4). Are you a manufacturer?

Yes, Jinan Wanyou has been fabricating pulp molding machine since 2008. We are one of the

most important pulp molding machine manufacturer in the world, and we are experienced pulp

molding machine manufacturer in China, providing high quality and production capacity pulp molding

machinery at reasonable prices to the world.(5). How to contact you?

Visit us.Our head office is in Building5-407,Xinyuanxin Business Center,HuaLong Road, Licheng District, Jinan City, P.R. China.

The nearest airport Jinan International Airport

(B) Send email to tell us your requirement.

(C) Call us at +86-15665703348(6). In how many countries have your machines been installed ?

All over the world, including the following countries: Algeria, Nigeria, Malawi, Romania, Mali, Cameroon, Philippine, Vietnam, Malaysia, Ghana, South Africa, Uzbekistan etc. -

Egg Tray Mold Quantity

12pcs(3pcs*4 faces)

Raw material

Waste paper

Egg tray Capacity

2000pcs/hour

Net weight per piece (gram)

70g-75g

Waste paper consumption

115-150kg / hour

Water Consumption

0.45-0.5ton / hour

Natural Gas Consumption of Dryer

50-75cbm/h

Worker requirement

5-7workers

Machine Length

8m-32m

Machine weight

8-32tons

Power Requirement

Without dryer

70KW

With dryer

100KW

Area of workshop

Without dryer

More than 200 M²

With dryer, dryer-20m

More than400M²

Container Requirement

Without dryer

20ft*1

With dryer

40hq*2+20ft*1

Remarks:

1. The egg tray Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g).

2. Workshop size is for reference only and could be adjusted according to actual size of client’s plant.Forming system

Including

12 moulds (3*4)forming machine

Vacuum pump

Compressor

Mold Washer

Vacuum tank

Air tankDrying system

Including

Drying oven

(L 18M*W2M*H2.2M)

Chain and tray

Hot air pipe

Chain wheel with shaft

Delivery belt

Drive motorBoiler

Including

Boiler

Natural gas burner(Riello)

Fan with motor

Electric control

Previous Article

Next Article

Previous Article

Next Article

Get a Free Quote

INSTALLATION AND DEBUGGING

- About 5-30 days installation and debugging;

- Technical consultation;

- Detailed design of customer workshop;

- Installing and testing the whole production line before shipment

TRAINING

-

Training engineers and workers;

-

About 2-5 days Training;

-

The engineer takes photos and videos in each step.

-

Take notes and ask the customer to signature for each step completion.

MAINTAINING

-

Remote after service. When there’s something wrong with the electric appliance software of the forming machine in customer’s factory, Jinan Wanyou company will remote check by network.

-

Reply within 12 hours.

-

Solutions are given within 24 hours.

-

Ensure timely, efficient and low cost of solving problem.

AFTER SALES SERVICES

-

We present Spare parts(1 year for free usage)

Suggest customer to buy necessary Spare Parts and Quick-Wear part for 2 years. -

Whole machine main part guaranteed for 2 years.

-

10 years for the forming machine lifetime.

-

20 years industry experience in the paper egg tray machine.

Questions & Answers

Q

Can we visit the factory?

A

Welcome at any time, and provide pick-up service.

Q

What are the ways of equipment installation and maintenance?

A

The equipment is easy to install and maintain. We randomly match the manual and spare parts of wearing parts, and can provide offline on-site support during the warranty period. Lifetime free online service.

Q

Where is the transportation port?

A

Usually Qingdao port, or customer-specified port.

Q

How long does it take for delivery?

A

The delivery time is different for different models, usually 2 to 3 months.

Q

What payment methods do we support?

A

TT, LC mainly.

Series of Products